PRAEFURNIUM SEAMLESS TUBES SEAMLESS PRAEFURNIUM TUBES PRAEFURNIUM Fistulam

Descriptio

Fistulae boiler one of seamless pipe is a.Vestibulum methodi eadem est cum tubo inconsutilem, sed strictius ad fistulas fabricandas necessarias habet.Secundum gradum temperaturae, tubus boiler divisus est in tubos generales boiler et altae pressionis fistulam boiler.

Modi productio:

① Temperatura tubus boiler generalis infra 450 est, utens fistulam calidum revolventem vel frigidum ductum fabricare fistulam ferream.

② summus pressura boiler tubus saepe in condicionibus caliditatis et pressionis altae organi adhibetur, effectus caliditatis flue gas et vaporum aquaticus, oxidatio et corrosio.Fistula chalybea cum magna ruptura roboris, alte resistentia oxygeni corrosio et stabilitatem bonam habent norma.

Tubuli proposita boiler;

① Tubulae boilis generalis maxime ad tubulas aquae muri fabricandas, tubulas in aqua ferventi et super fistulam vaporem calefactam, super calefactum vaporem motivum fistulae boiler, magnae et parvae fistulae fumi et fistulae lateris fistulae.

princeps pressura boiler tubus maxime adhibita est ad fabricam altam pressionem et ultra altam pressionem boiler super calefacientis tubos, fistulae reheat, airway, principale vaporis organi.

Categoria:

General tube boiler tube and high pressura boiler tube boiler tubes is exposed to high temperature performance.Tubae bullientes in genere, vel altae pressurae bullientes secundum eorum usum in variam fistulam ferream dividi possunt.

Specification

Signa et materia ad fistulam chalybem praesto sunt ad materiam carbonis, mixturae, et materiae immaculatae.

Chalybe:ASTM/ASME A/SA 106, ASTM A179, ASTM A192, ASTM/ASME A/SA 210, ASTM A333 Gr 1, 6,7 to Gr 9,

Admisce ferro:ASTM/ASME A/SA 213 T1, T2, T5, T9, T11, T12, T22, T91, T92;ASTM A335 P1, P2, P5, P9, P11, P12, P22, P91, P92

DiverASTM A268, ASTM A213, TP304/L, TP316/L, 310S,309S,317,317L,321,321H, et duplex materia immaculata ferro etc.

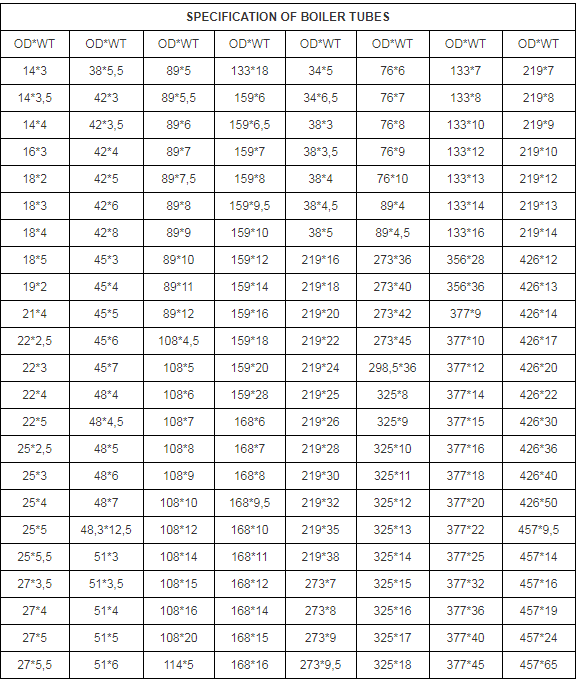

Communia Amplitudo: OD ab 6mm ad 1240mm, crassitudo ab 1mm ad 50mm .

Genera:Recta tibia boiler, et U boiler ferrei fistula pro tubi fasciculo commutatoris.

Haec signa denotant classificationem, magnitudinem, figuram, pondus et licitam declinationem, technicam requisitionem, inspectionem et experimentum, packaging, notatio et qualitas certificatorium inconsutilem fistulae ferri ad boiler.

Signa

GB (Sinica National signa)

(1) GB 3087: Seamless chalybe tubes for low and middle pressure boiler .

(2) GB 5310: Seamless chalybe tube for high pressure boiler .

(3) GB 13296: Seamless chalybe tubes for boilers and heat exchangers

(4) GB 6479: Seamless chalybe tubes for high-pressura chemica stercorat armorum

(5) GB 9948: Seamless chalybe tube for petroleum crepuit

ASME (societas mechanicarum mechanicarum)

(1) ASME SA-106: Standard Specification for Seamless Carbon Steel Pipe for High-Tempature Service

(2) ASME SA-192M: Seamless Carbon Steel boiler tubes for high pressure

(3) ASME SA-209M: Seamless carbon-Molybdenum Alloy-Steel Boiler et Super calefacientis tubes

(4) ASME SA-210M: Seamless Medium-carbon Ferro Boiler et Superheater Tubes

(5) ASME SA-213M: Inconsutilem ferriticum et austeniticum stannum chalybis boiler, superheatris et caloris fistulae commutatoris.

ASME SA178: Electric-Resistentia iuncta Carbon Steel et Carbon-Manganese Ferro Boiler et Superheater

ASTM (Sinica National signa)

(1) ASTM A213: Inconsutilem ferriticum et austeniticum stannum chalybis boiler, superheatris et caloris fistulae exchanger

(2) SA213-T2: ASME SA213 T2 licita sunt passiones in ASME Boiler Codicis usque ad 1000F recensita.

(3) SA213-T9

(4) SA213-T12: Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, Heat-Exchanger tube.

(5) SA213-T11: Fistulae in cambiatoribus calidis, super calentibus et in boilo- ribus adhibentur.

SA213-T22: ASM T22 Tubus Boilerus est tubus tolerantiae temperatus qui in ambitibus acidicis et corrosivis adhibetur ut processus hydrochlorici et in aluminio chloridi catalysti applicationes involventium.

(7) ASTM A 106M: Seamless Carbon Steel Pipe for High-Tempature Service

(8) ASTM A192M: Seamless Carbon Steel boiler tubes for high pressure

(9)ASTM A210M: Seamless Medium-carbon Ferro Boiler et Superheater Tubes

(10) ASTM A 335M: Fistula ferritica inconsutilis mixtura chalybea pro servitio summus temperatus

EN(Deutsche industrie normen)

EN 10216-2 : Seamless chalybe tubes for pressure purposes

DIN

Signa (XVII)CLXXV: Inconsutilem fistulae calor resistens Steels - Technical Conditions of Delivery

JIS

(1) JIS G3461: Carbon ferri boiler et caloris fistulae commutatoris

(2) JIS G3462: Admisce ferrum boiler et caloris fistulae exchanger

(3) JIS G3463: Steel for boiler and heat Exchanger tubes

STEELS

SA213-T304;– SA 213 Tp 304 Materia constat ex 18% chromium et carbo, manganeso, phosphoro, sulphure, pii et nickel in compositione.

SA213-T316;- SA213 TP316 Tube est vexillum materiale pro tubulis commutatoriis calidis qui fiunt ex 316 austenitico ferro immaculato.

SA213-TP321 & 347- SA213 TP321 specificatio est fistulae commutatoris caloris quae fiunt ex 321 austenitico ferro immaculato.

Painting&Coating

Bare, leviter unctum, Nigrum/Red/Yellow Painting, Zinc/Anti-mordax coating

Stipare&Loading

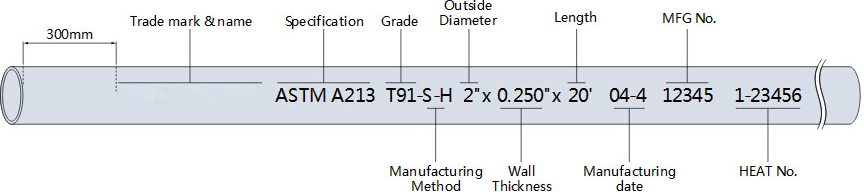

Standard Marking