ASTM A53 Steel Seamless Pipe Carbon Seamless tube Seamless Steel Pipe

Introductio

ASTM A53 Gradus B est materia sub vexillo ferreo Americano tibiae, API 5L Gr.B est etiam materia vexillum Americanum, A53 GR.B ERW refert resistentiam electricam fistulam ferri iunctam A53 GR.B;API 5L GR.B Conflatum refert ad materiam fistulae ferri iunctae API 5L GR.B.

A53 fistula fit in tribus generibus (F, E, S) et duobus gradibus (A, B).

A53 Typus F fabricatur cum fornace ludibrio pugillo vel pugillo continuum habere potest (Grade A only)

A53 Type E pugna electrica resistentiam habet (Grades A et B)

A53 Type S fistula inconsutilis est et in Gradibus A et B invenitur)

ASTM A53 fistula (etiam ASME SA53 fistula appellata) ad applicationes mechanicas et pressiones disposita est, et ad usum generalem in vapore, aqua, gas et aere lineae apta est.Convenit ad operationes glutino et formandas etiam flexae, flexae et languae, aliquibus requisitis obnoxiae.

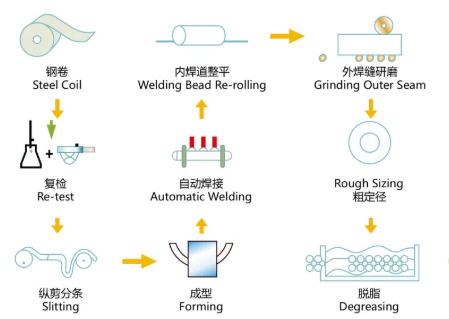

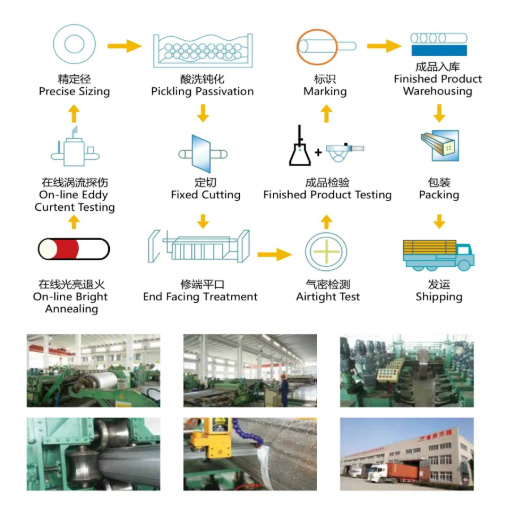

Processus productionis

Technical data

| Gradus | C, max | Mn, max | P, max | S, max | Cu*, max | Ni*, max | Cr*, max | Mo*, max | V*, max | |

| Typus S (seamless) | A | 0.25 | 0.95 | 0.05 | 0.05 | 0.4 | 0.4 | 0.4 | 0.15 | 0.08 |

| B | 0.3 | 1.2 | 0.05 | 0.05 | 0.4 | 0.4 | 0.4 | 0.15 | 0.08 | |

| Typus E (Resistentia Electric iuncta) | A | 0.25 | 0.95 | 0.05 | 0.05 | 0.4 | 0.4 | 0.4 | 0.15 | 0.08 |

| B | 0.3 | 1.2 | 0.05 | 0.05 | 0.4 | 0.4 | 0.4 | 0.15 | 0.08 | |

| Type F (fornace iuncta) | A | 0.3 | 1.2 | 0.05 | 0.05 | 0.4 | 0.4 | 0.4 | 0.15 | 0.08 |

Tota compositio horum quinque elementorum 1.00% non excedunt.

depictio producti

Carbon Steel Seamless Pipe Description

| Product Name | Seamless Carbon ferro tibia | |

| Magnitudo | OD | 12.7mm-710mm |

| Crassitudo | 3mm-45mm | |

| Longitudo | SRL, DRL, 5.8M,11.8M | |

| Steel Material | ASTM A53/A106,API 5L,EN10216,DN162ASTM A179 A192 A210 | |

| Steel Gradus | Gradus A,Grade B,Grade C,X42,X52.S235JRH,S355,P265 ect. | |

| Processus | Hot advolvit / calidum expansionem / frigus instructa / frigus advolvit | |

| Consuetudinem | Princeps temperatus ministerium | |

| Superficies | Bared Black Painting, Galvanized, Coating | |

| Proctor | Plastic cap | |

| sarcina | Fasciculi, Bulk | |

| inspicienda | Cum HYDRAULICUS Testis, Ultrasonic probatio seu X-ray Test | |

| Testimonium | ISO9001, MM | |

| Date of Delivery | Secundum quantitatem dierum 15/20/25/30/40/50/60 minus | |

| Mercedem: | L/C vel T/T | |

A.Chemical compositio in % Pro API 5L PSL1

| EXEMPLUM | Gradus ferro | C . | Si | Mn. | P | S |

| API 5L PSL1 | B | ≤0.28 | - | ≤1.20 | ≤0.03 | ≤0.03 |

| API 5L PSL1 | X42 | ≤0.28 | - | ≤1.3 | ≤0.03 | ≤0.03 |

| API 5L PSL1 | X52 | ≤0.28 | - | ≤1.4 | ≤0.03 | ≤0.03 |

| API 5L PSL1 | X56 | ≤0.28 | - | ≤1.4 | ≤0.03 | ≤0.03 |

| API 5L PSL1 | X60 | ≤0.28 | - | ≤1.4 | ≤0.03 | ≤0.03 |

| API 5L PSL1 | X65 | ≤0.28 | - | ≤1.4 | ≤0.03 | ≤0.03 |

| API 5L PSL1 | X70 | ≤0.28 | - | ≤1.4 | ≤0.03 | ≤0.03 |

B.Mechanical Properties pro API 5L PSL1

| EXEMPLUM | gradus | Distrahentes fortitudo (Mpa) | Cedat imperium (Mpa) | Prolongatio |

| API 5L PSL1 | B | ≥415 | ≥245 | Sicut per API 5L |

| API 5L PSL1 | X42 | ≥415 | ≥290 | Sicut per API 5L |

| API 5L PSL1 | X52 | ≥460 | ≥360 | Sicut per API 5L |

| API 5L PSL1 | X56 | ≥490 | ≥390 | Sicut per API 5L |

| API 5L PSL1 | X60 | ≥520 | ≥415 | Sicut per API 5L |

| API 5L PSL1 | X65 | ≥535 | ≥450 | Sicut per API 5L |

| API 5L PSL1 | X70 | ≥565 | ≥483 | Sicut per API 5L |

C.Chemical compositione in % Pro API 5L PSL2

| Level | Gradus ferro | C . | Si | Mn. | P | S |

| PSL2 | B | ≤0.24 | - | ≤1.20 | ≤0.03 | ≤0.03 |

| PSL2 | X42 | ≤0.24 | - | ≤1.3 | ≤0.03 | ≤0.03 |

| PSL2 | X52 | ≤0.24 | - | ≤1.4 | ≤0.03 | ≤0.03 |

| PSL2 | X56 | ≤0.24 | - | ≤1.4 | ≤0.03 | ≤0.03 |

| PSL2 | X60 | ≤0.24 | - | ≤1.4 | ≤0.03 | ≤0.03 |

| PSL2 | X65 | ≤0.24 | - | ≤1.4 | ≤0.03 | ≤0.03 |

| PSL2 | X70 | ≤0.24 | - | ≤1.4 | ≤0.03 | ≤0.03 |

D.Mechanical Properties For API 5L PSL2

| Level | gradus | Distrahentes fortitudo (Mpa) | Cedat imperium (Mpa) | Prolongatio |

| PSL2 | B | 415-760 | 245-450 | Sicut per API 5L |

| PSL2 | X42 | 415-760 | 290-495 | Sicut per API 5L |

| PSL2 | X52 | 460-760 | 360-530 | Sicut per API 5L |

| PSL2 | X56 | 490-760 | 390-545 | Sicut per API 5L |

| PSL2 | X60 | 520-760 | 415-565 | Sicut per API 5L |

| PSL2 | X65 | 535-760 | 450-600 | Sicut per API 5L |

| PSL2 | X70 | 565-758 | 483-621 | Sicut per API 5L |

Transportatio

Express (Sample Delivery), Aer, Rail, terra, mare shipping (FCL vel LCL vel mole)